Energy auditors may use thermography—or infrared scanning—to detect thermal defects and air leakage in building envelopes.

How They Work

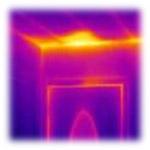

Thermography measures surface temperatures by using infrared video and still cameras. These tools see light that is in the heat spectrum. Images on the video or film record the temperature variations of the building’s skin, ranging from white for warm regions to black for cooler areas. The resulting images help the auditor determine whether insulation is needed. They also serve as a quality control tool, to ensure that insulation has been installed correctly.

A thermographic inspection is either an interior or exterior survey. The energy auditor decides which method would give the best results under certain weather conditions. Interior scans are more common because warm air escaping from a building does not always move through the walls in a straight line. Heat loss detected in one area of the outside wall might originate at some other location on the inside of the wall. Also, it is harder to detect temperature differences on the outside surface of the building during windy weather. Because of this difficulty, interior surveys are generally more accurate because they benefit from reduced air movement.

A thermographic inspection is either an interior or exterior survey. The energy auditor decides which method would give the best results under certain weather conditions. Interior scans are more common because warm air escaping from a building does not always move through the walls in a straight line. Heat loss detected in one area of the outside wall might originate at some other location on the inside of the wall. Also, it is harder to detect temperature differences on the outside surface of the building during windy weather. Because of this difficulty, interior surveys are generally more accurate because they benefit from reduced air movement.

Thermographic scans are also commonly used with a blower door test running. The blower door helps exaggerate air leaking through defects in the building shell. Such air leaks appear as black streaks in the infrared camera’s viewfinder.

Thermographic scans are also commonly used with a blower door test running. The blower door helps exaggerate air leaking through defects in the building shell. Such air leaks appear as black streaks in the infrared camera’s viewfinder.

Thermography uses specially designed infrared video or still cameras to make images (called thermograms) that show surface heat variations. This technology has a number of applications. Thermograms of electrical systems can detect abnormally hot electrical connections or components. Thermograms of mechanical systems can detect the heat created by excessive friction. Energy auditors use thermography as a tool to help detect heat losses and air leakage in building envelopes.

Infrared scanning allows energy auditors to check the effectiveness of insulation in a building’s construction. The resulting thermograms help auditors determine whether a building needs insulation and the location in which it should go. Because wet insulation conducts heat faster than dry insulation, thermographic scans of roofs can often detect roof leaks.